UNDER

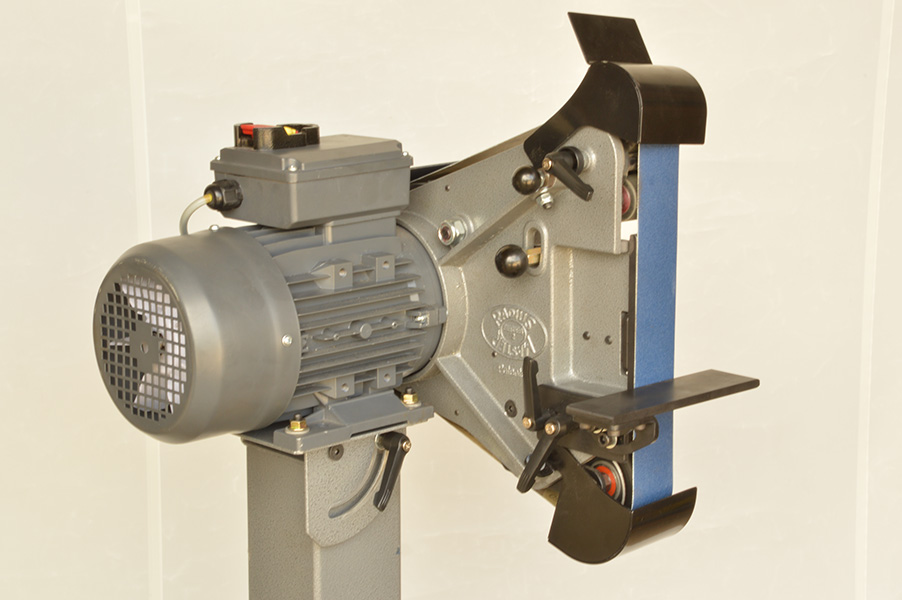

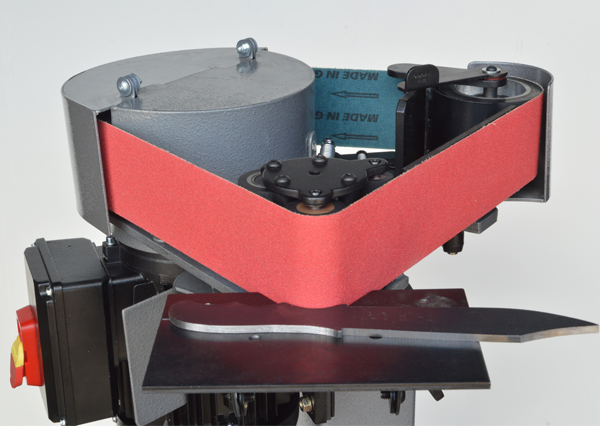

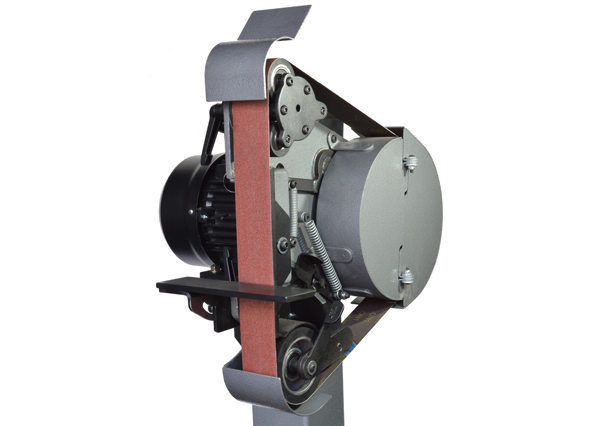

“An innovative belt grinder with seven different workstations on one belt”

- Unmatched tracking accuracy allowing sharp corner notching

- Belt changes in less than ten seconds.

- The most compact user-friendly machine worldwide.

- Worldwide Distribution.

Our Best Belt Grinders – Australian Made

Australian Made Award Winning Precision Belt Grinder Machinery

Radius Master belt grinders are the most versatile and accurate belt grinders in the world.

Designed and built in Australia from high quality parts with an unmatched performance and quality, there’s no need for add-ons and spanners with these belt grinders.

About Us

Belt Grinder Video Demonstrations

Original Belt Grinder Summary

A high performance belt grinding machine that outperforms the competition.

Variable Speed Belt Grinder

Step-less control from 400rpm to 1600rpm for difficult to grind materials.

Belt Grinder Demonstration

Ben Orford’s demonstration of the features and utility of the RM48 Belt Grinder